How to remove the breaks such as taps, drills, screws, etc.

The common point of tools such as taps and drill bits is that the center part is a solid body. Therefore, the middle solid part can be broken, and the tap and the drill bit can be taken out.

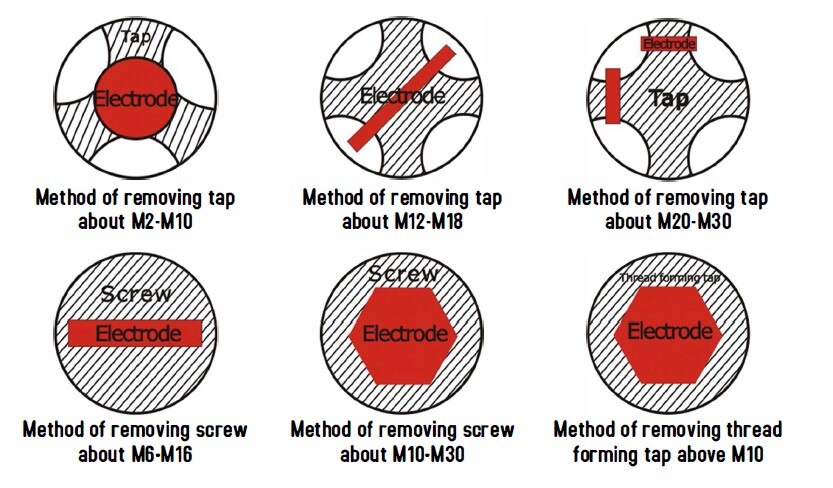

As shown below:

Taps with a normal thread smaller than M12 can be removed by breaking the center. In the case of a tap having an excessively large thread, the diameter of the central part is too large, and it may be divided into two pieces or the four corners by sheet electrode to take them out. When the drill bit is broken, we can burning its central part and then take it out. In practical working, the electrode does not have to be processed all the way down. When it reaches a certain depth, nose up the work head, and use a chisel,tweezers, magnet to remove the debris, and then restart the processing. This way can reduce the discharge area and speed up the processing.

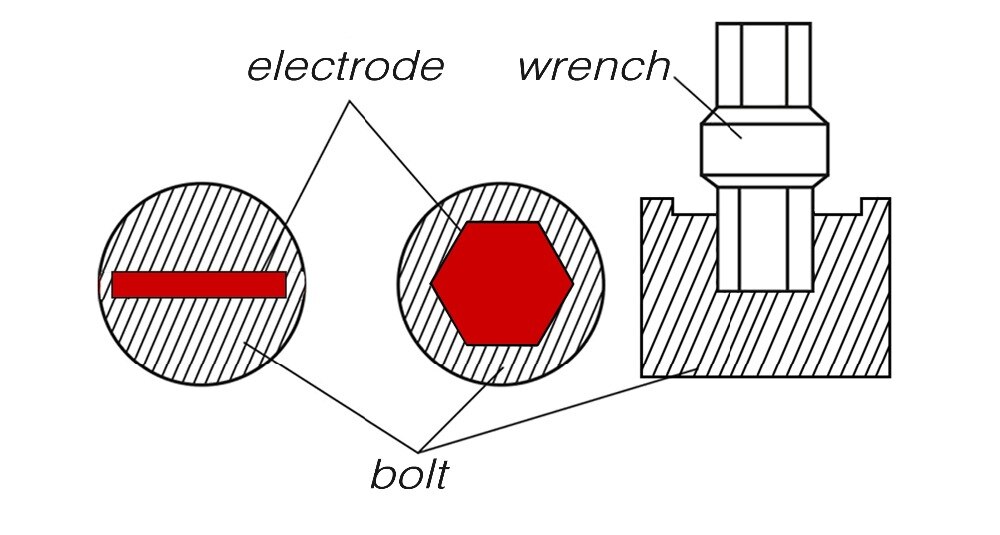

When the screw or bolt below grade 8.8 is broken in the work piece, you can burn a small hole in the center of the end face, tap a reverse thread and screw on the screw, or use a broken screw extractor to unscrew it. If the bolt diameter is too large or the strength grade is higher than 8.8, the general method is not working, you can use a sheet electrode to make a 2-3mm groove on the section, then use a screwdriver to screw it out, or use a hexagonal electrode to make a groove, then use a hexagonal wrench to unscrew it; if the position is too deep, the general broken screw extractor can not reach into the hole, then you can use the hexagonal transition wrench to deepen it into the deep groove. As shown below:

Post time: 10-18-2019