Maintenance-free Oil-water Separator Working Principle

Oil-water separation technology is of great significance in all kinds of waste-water treatment processes. A well-designed oil-water separator can save costs of operation and maintenance for decades in future.

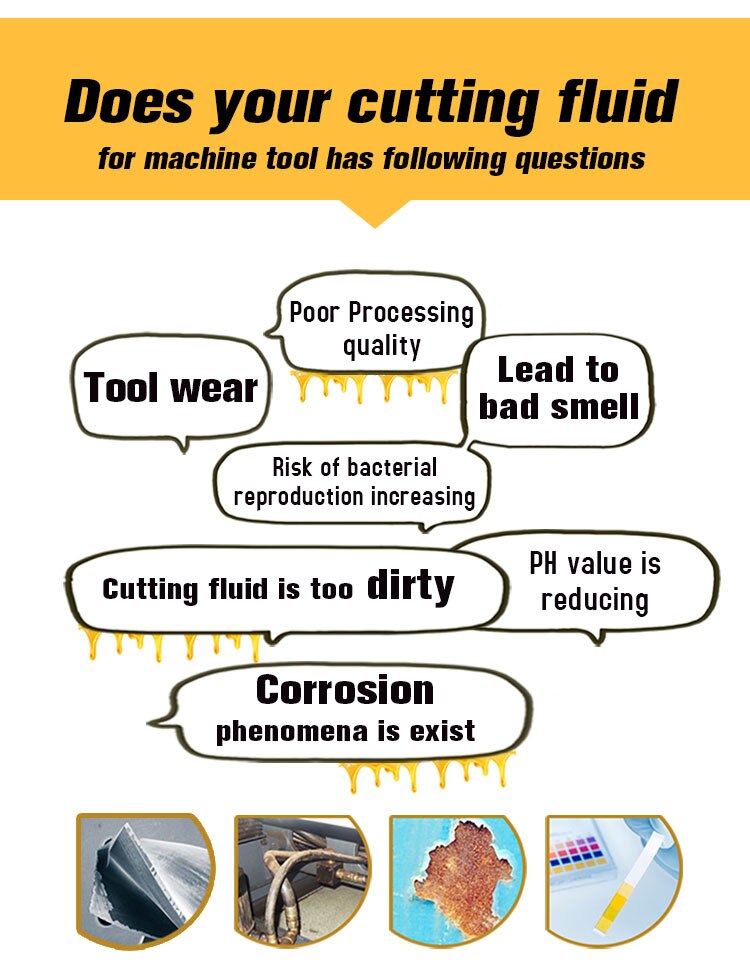

Studies have shown that when the oil on the surface of the cutting fluid causes oxygen deficiency in the water tank, the reproduction of anaerobic is very amazing in the cutting fluid of the machine tool. When the bacterial content of the cutting fluid is more than 106 / ML, the cutting fluid will deteriorate and smell. It can pollute the surrounding environment and influence workers' health. Timely remove the oil in the cutting fluid and keep the cutting fluid clean, which can effectively inhibit the growth of bacteria!

Although the basic functions of a separation device may seem simple, there are significant differences in different technologies or systems that determine the cost of operation and maintenance per year. Therefore, when selecting separation techniques, key indicators and data should be carefully analyzed.

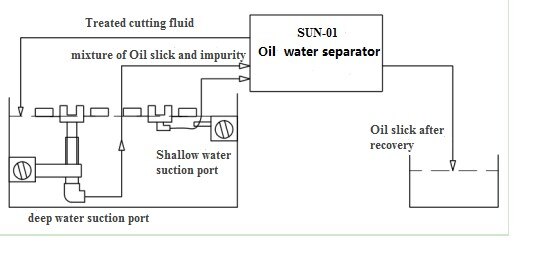

However, compared with many problems of the traditional oil-water separator, the oil-water separator with maintenance-free has been more and more widely welcomed. Let us first understand the working principle of the maintenance-free oil-water separator:

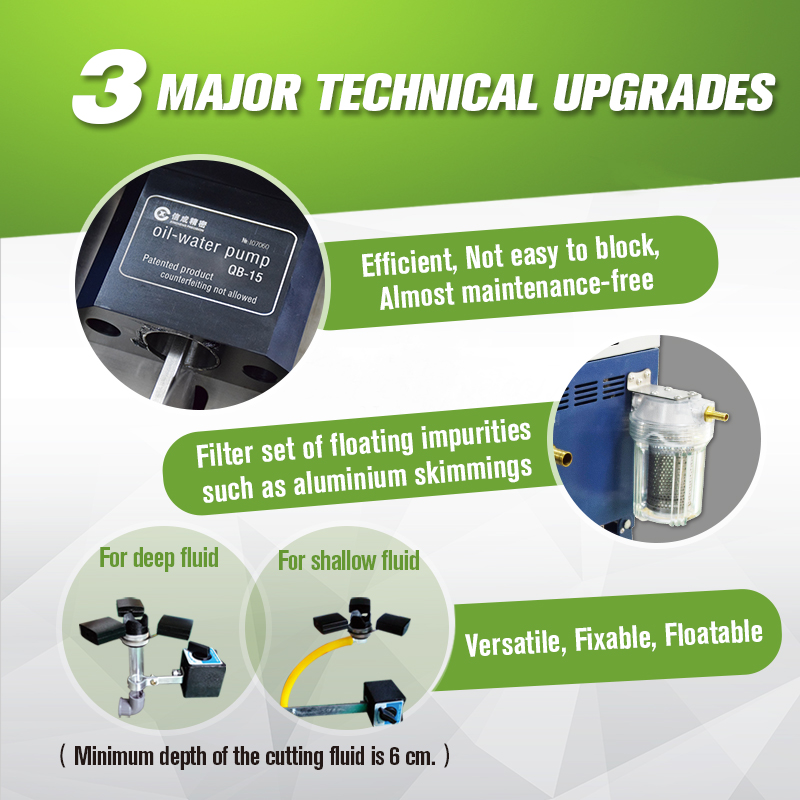

This small oil-water separator is of a compact internal structure and space saving, which can be used without stopping the machine tool, saving working time and recycling the cutting fluid. Three-stage separation of the cutting fluid mixture inside the chassis is also very strong in separating oil.

If you still worry: there will be particles blocking the pipeline, the designer has been thought of it, the filter is used to filter out large particles in the water inlet in advance, so a practical and economical oil-water separator is born!

Post time: 09-21-2019