Application of EDM machine

Due to the flexibility of metal processing, EDM is widely used in the machinery industry and is highly praised! However, in the face of many types of EDM machines on the market, many masters will be confused. They don't know what kind of machining can be done by the EDM machine. So, here are some typical situations for you. !

-

Working condition ①: Batch punching φ0.3~3mm, the speed and precision requirements are relatively high, and the parts are moderately sized.

-

Countermeasure: In this case, it is suitable to use the CNC EDM punching machine.

-

Firstly, select the appropriate tooling to clamp the parts in batches, position them, and then program according to the perforation requirements. Since the accuracy of the three-axis CNC system is high, the precision of the finished products after processing is enough to meet the requirements, and the speed is also fast, up to 60mm. /min.

-

Working condition ②: Batch punchingφ0.3~3mm, the parts are large, the piercing position is not good, and the parts can't move.

-

Countermeasure: In this case, the difficulty lies in the fact that the parts are large and cannot be placed in the table of the desktop puncher, or the punching position is not good, and it cannot be moved. At this time, the portable EDM puncher can come in handy.

-

Place the portable EDM on the empty ground next to the work-piece, then place the work head on the parts to be processed, connect the wiring and the high-pressure water pump, and then start processing. The disadvantage is that the speed is slightly slower, about 20mm/min. .

-

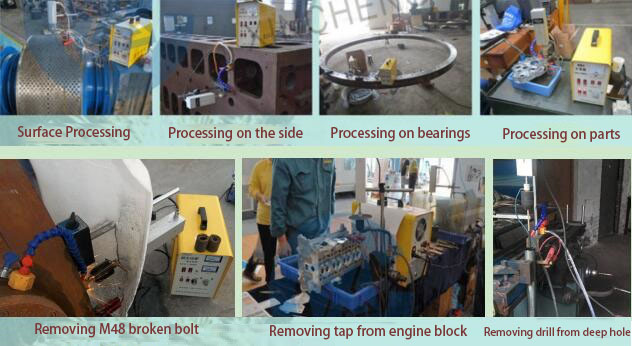

Working condition ③: Punching φ1 ~ 10mm, speed and accuracy requirements are not high / Remove the broken taps, screws and so on in the work-piece.

-

Countermeasure: A small portable EDM tap burner can achieve both of these requirements, and the price is lower than the EDM puncher.

-

In terms of punching, it is recommended to select a large power, about 1500W/3000W, and the punching speed will be faster; In terms of removing the tap, if it is manual, with the skill of the technician, it is difficult to take it out without loss and quickness. With a professional portable EDM, you can do more with less! No matter the hook surface, large parts, mufti-angle machining, and extra large bolts, don't worry.

-

Working Condition ④:Marking

-

Countermeasures: In addition to laser marking or lettering, in some cases with EDM marking is also a good choice!

-

First, make the mold according to the text or pattern that needs to be engraved. Then fix the mold electrode to the drill chuck under the machine head and start processing.

After reading this, do you have a basic understanding of the processing of EDM machines under different working conditions? If you have more experience, you can speak your mind and welcome more comments!

Luoyang Xincheng Precision Machinery Co.,Ltd

23.11.2019

Post time: 11-23-2019